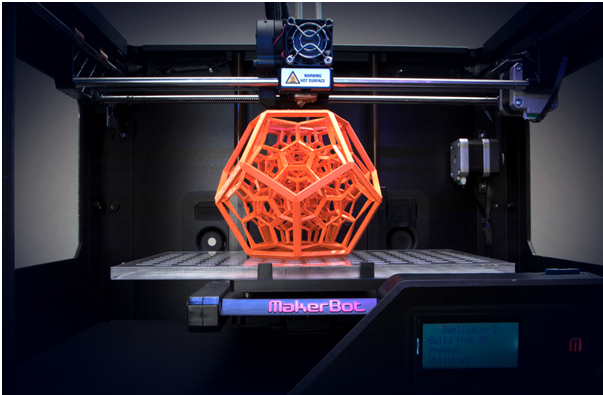

A collection of methods is known as rapid prototyping. It may help to produce prototypes fast and economically. Three-dimensional computer-aided design (CAD) software maintains a 3D model of a part product manufacturing (also known as 3D printing) processes to produce the part. The automotive industry was the first to adopt rapid prototyping to create scale models.

Prototypes don’t have to be exact reproductions of the final product, though they often are. Hence, prototypes can range from low-fidelity products that product designers quickly create to test a more general concept to high-fidelity prototypes that must resemble the anticipated final product in terms of appearance and functionality.

What advantages do rapid prototypes offer?

It’s a great deal safer

When presenting your work to the client or your supervisor, rapid prototyping reduces the element of surprise. And that’s a good thing when it comes to large, expensive enterprises. Engaging stakeholders early in the development process increases the likelihood that you’ll produce something they’ll appreciate by allowing them to provide feedback as you work. Their bank account will benefit, but so will your professional relationship.

Permitting Function Testing

Your prototype accurately depicts how your final product will appear and function. Your ideas are improved upon to create the designs that are most likely to succeed by testing and retesting them. Provides a good user experience, or not? Your objectives are met, right? At this point, you can identify the elements that still require some improvement and possible growth areas.

It is quicker

Rapid prototyping allows you to avoid wasting time that otherwise is used to remedy broken things. Also, it is generally an approach to operate. Even though stopping to get feedback may seem slower than moving forward, doing so might speed up the decision-making process.

An authorised design can be reached, for instance, far more quickly by a designer who collects information on a website’s user experience (UX) at each stage than by someone who completes everything at once and then revises it repeatedly.

It dispels the paralysis through analysis (and boosts creativity)

You could go through a period of analysis paralysis when a lot depends on a decision you’re not making if it’s the proper one. Rapid prototyping offers this potential because adjustments to something with more minor details are considerably simpler to do. You’re dealing with a simplified version, so your judgement isn’t based on as much information.

It encourages teamwork

Regular communication with a wide range of people, from stakeholders to high management, is necessary for rapid prototyping. Cooperation is encouraged as the foundation for a good relationship between team members and between the team and stakeholders. The familiar alliance fosters a sense of collective ownership of the project, which enhances everyone’s drive and focuses.

Increasing User (and Stakeholder) Participation

Prototypes promote cooperation and helpful criticism from sources. You can construct a high-fidelity prototype for users and stakeholders to examine after creating a low- to medium-fidelity prototype that satisfies your requirements.

Finding and Assessing Product Risks Ergonomically

Product designers can find possible product compliance and safety issues using prototypes. This stage allows you to address any risk issues in your design by moving from form to function.