The performance of an X‑ray system is closely tied to the quality and stability of its electrical components. The power supply of the X‑ray machine is a critical factor that determines the efficiency, image quality, and operational reliability of these advanced devices. Even slight fluctuations in energy delivery can result in inconsistent imaging, equipment wear, or safety hazards. For applications in medical diagnostics, industrial inspection, and security screening, maintaining a stable and high-quality power supply ensures precise and reliable results, protecting both equipment and users.

Consistent Imaging Quality

Stable energy delivery is essential for producing clear and accurate X‑ray images. Variations in voltage or current can directly affect the intensity of X-ray emissions, leading to distorted or uneven images. A reliable power system allows operators to achieve repeatable results, critical for both clinical diagnosis and industrial evaluation.

- Uniform voltage output: Prevents fluctuations that can compromise image clarity and diagnostic accuracy.

- Minimized imaging artifacts: Reduces noise, streaks, or distortions, ensuring precise imaging results.

- Reliable operation: Supports continuous scanning without sudden interruptions that could disrupt workflow or testing processes.

Protection of High-Voltage Components

X-ray machines contain delicate components, including tubes, detectors, and generators, which are highly sensitive to electrical stress. A high-quality power system safeguards these components, extending their lifespan and maintaining consistent performance over time.

- Circuit protection: Prevents overloads that could damage control circuits or high-voltage components.

- Tube longevity: Reduces thermal and mechanical stress on the X-ray tube, minimizing premature wear.

- Lower maintenance costs: Stable power decreases the frequency of repairs and component replacements.

Efficiency in Operation

Optimized power management contributes to energy efficiency and ensures that all system components function at their designed capacity. This is particularly important in facilities with high throughput or continuous use, such as hospitals, research labs, and manufacturing plants.

- Reduced energy waste: Efficient power delivery ensures energy is used effectively, reducing operational costs.

- Performance under high load: Machines maintain optimal output even during intensive scanning sessions.

- Sustainability: Less energy consumption leads to reduced environmental impact and supports sustainable operations.

Advanced Imaging Feature Support

Modern X-ray machines often include advanced features such as 3D imaging, automated scanning protocols, and digital detectors. The power supply has a direct impact on the performance of these technologies, influencing the accuracy and speed of imaging.

- Digital detector reliability: Stable energy ensures accurate signal processing and high-resolution images.

- Precision timing: Consistent power allows for rapid exposures and high-frequency imaging sequences.

- Automation efficiency: Motorized tables, positioning systems, and software-driven imaging modules operate smoothly with regulated power.

Safety for Operators and Patients

X-ray machines operate with high-voltage energy, making electrical stability crucial for safety. A reliable power system minimizes hazards and ensures compliance with safety standards, protecting both operators and patients.

- Voltage control: Maintains safe energy levels, reducing the risk of electrical shock or arcing.

- Fault detection: Early detection of anomalies allows machines to shut down safely before damage occurs.

- Standards compliance: Reliable power management supports adherence to safety certifications, such as ISO or CE, ensuring regulatory compliance.

Versatility Across Applications

X-ray machines are used in healthcare, industrial inspection, security, and research. A robust power system supports different operational modes, from rapid screening to detailed diagnostic imaging, ensuring consistent results across various applications.

- Scalable energy delivery: Supports diverse imaging requirements without compromising output quality.

- Cross-industry reliability: Maintains consistent performance whether used for luggage inspection, medical diagnostics, or industrial non-destructive testing.

- Customizable settings: Allows operators to fine-tune voltage and current to match specific application needs.

Coordination with X-Ray Generators

The performance of an X-ray machine heavily relies on the integration of its power supply with the generator. Collaborating with experienced X Ray generator manufacturers ensures optimal energy management, precise emissions, and reliable operation.

- Accurate energy delivery: Provides the generator with stable voltage and current for consistent X-ray output.

- Reduced warm-up time: Stable power allows systems to reach readiness quickly, improving workflow efficiency.

- Longer generator lifespan: Smooth operation minimizes wear on high-voltage components, reducing maintenance frequency.

Simplified Maintenance and Monitoring

Modern power supplies often include monitoring and diagnostic features, which simplify maintenance and reduce unplanned downtime. These systems track voltage, current, and performance metrics in real time, enabling proactive management.

- Real-time monitoring: Detects anomalies before they cause equipment failure, preventing operational disruptions.

- Predictive maintenance: Power data helps schedule timely service, reducing unexpected downtime.

- Troubleshooting support: Consistent power simplifies the identification of electrical or mechanical issues, speeding up repairs.

Performance in Challenging Environments

X-ray machines may operate in areas with fluctuating power, unstable grids, or variable environmental conditions. A resilient power system ensures consistent performance even under such challenging circumstances.

- Spike and surge protection: Shields sensitive components from voltage fluctuations.

- Backup power integration: Supports short outages, ensuring uninterrupted operation for critical scanning.

- Environmental adaptability: Maintains functionality in diverse conditions, including temperature or humidity variations, safeguarding imaging reliability.

Longevity and Return on Investment

The investment in a high-quality power supply directly affects the longevity and value of an X-ray machine. Reliable energy management enhances performance consistency, reduces wear on components, and maximizes return on investment.

- Extended system lifespan: Reduces stress on the tube, generator, and circuitry for prolonged operational life.

- Lower operational costs: Fewer repairs and replacements save on parts and labor expenses.

- Maximized ROI: Consistent imaging quality ensures that the machine delivers dependable results over time.

Conclusion

A dependable X-ray machine power supply is crucial for maintaining consistent performance, safety, and longevity across all X-ray applications. From ensuring stable imaging and protecting sensitive components to supporting advanced features and efficient operation, the power system forms the foundation of a high-functioning X-ray setup. Partnering with reputable providers guarantees machines receive optimized energy management, safeguarding performance and reliability.

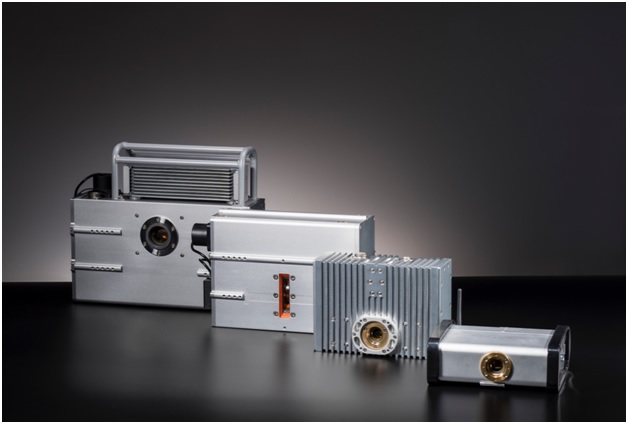

VJ X-Ray is a recognized leader in integrated X-ray solutions, offering high-quality systems and power supply components tailored for medical, industrial, and security applications. With decades of engineering expertise, global reach, and a focus on precision, VJ X-Ray ensures machines operate at peak performance, delivering reliable imaging, reduced downtime, and long-term value for operators worldwide.